×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Spectra Sway Bar Link

Stabilizer Sway Bar Link- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Sway Bar Links found

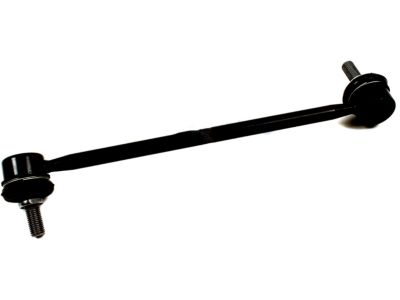

Kia Spectra Link Assembly-Front Stabilizer

Part Number: 548302F000$41.97 MSRP: $60.57You Save: $18.60 (31%)Ships in 1-3 Business Days

Kia Spectra Link Assembly-Front Stabilizer

Part Number: 548402F000$43.71 MSRP: $63.07You Save: $19.36 (31%)Ships in 1-3 Business DaysKia Spectra Link Assembly-Rear Stabilizer

Part Number: 5553017010$23.50 MSRP: $33.62You Save: $10.12 (31%)Ships in 1-3 Business DaysKia Spectra Link Assembly-Control,LH

Part Number: 0K2N134170A$40.94 MSRP: $59.09You Save: $18.15 (31%)Ships in 1-3 Business DaysKia Spectra Link Assembly-Control,RH

Part Number: 0K2N134150A$40.94 MSRP: $59.09You Save: $18.15 (31%)Ships in 1-3 Business DaysKia Spectra Link Assembly-Rear Stabilizer

Part Number: 5553017000$24.81 MSRP: $33.62You Save: $8.81 (27%)Ships in 1-3 Business DaysKia Spectra Link Assembly-Control

Part Number: 0K2A134150B$44.58 MSRP: $60.90You Save: $16.32 (27%)Ships in 1-3 Business Days

Kia Spectra Sway Bar Link

The Kia Spectra Sway Bar Link is an intricate part which dramatically increases Kia Spectra car performance and durability. The Sway Bar Link interlinks the sway bar to the control arm, and its main function is to minimize the body movements during cornering, which is essential for proper stability. This feature is of special significance for the different modifications of Kia Spectra inside which weight distribution and consequently handling, driving efficiency and safety increase. The Sway Bar Link is responsible for efficient transmission of motion from the control arm to the sway bar enabling better suspension system operation. This Kia Spectra Sway Bar Link is recognized for its durability that's why, it is on the top list of Kia car lovers. Compatibility with a number of Spectra models' means the drivers can get advantages of better suspensions in various models. Also, the Sway Bar Link has strategically designed with superior materials that can endure wear and tear on a vehicle thus supporting the car's market. From this article, one is able to deduce that the Sway Bar Link for Kia Spectra plays a significant role in the driving and safety features that are attributed to the vehicles' efficiency. As a conclusion, the Kia Spectra Sway Bar Link is an outstanding feature that speaks out loud about the company's policy on the production of high-quality vehicles with the use of new technologies.

If you're in search of top-notch, reasonably priced OEM Kia Spectra Sway Bar Link, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Spectra Sway Bar Link, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Spectra Sway Bar Link Parts Questions & Experts Answers

- Q: What are the steps involved in front stabilizer bar link and bushing removal and installation on Kia Spectra?A:The procedures that are used to remove the Sway Bar Kit entail the following where the crossmember of the suspension is lowered and the sway bar kit is taken from behind; normally where there is harm on the bar, it is due to severe influences accorded to it from accidents that may have affected other significant apparatus and thus called for professional repair. Start the procedure with the removal of the wheel lug nuts, lifting of the front part of the car and placing on stands together with an application of park brake and placing of the rear wheels on blocks. Wheels need to be removed first, then use an Allen wrench to hold the ballstud and knock the nut off to get the link off the lower Control Arm / strut. For the 1997 and the models prior to that, the links are secured to the lower control arms by a bolt; the 2002 models and the models that come after it, the links are mounted to the front struts. Third, it is necessary to take out the sway bar brackets and Sway Bar Bushing and check the bushings for cracks or tears; if the bushings are damaged, put a new one in their place. Next, clean the bushings and lubricate them with silicone lubricant or vegetable oil and then assemble the bushings on to the bar, brackets and bolts followed by tightening until the specified torque tightness is achieved. For the models of Sportage, it is necessary to remove the lower cross bar of sway bar kit of an engine/transaxle subframe, and besides it is needed to lower the mentioned member also. One has to take out the nuts on the sway bar link rods and the bolts uncovering the lower control arm ball joint and front exhaust pipe. With regards to the 4 wheel drive, the driveshaft needs to be detached from the vehicle and the oil of the transfer case needs to be drained. You also have to unbolt the rear flange assembly and depending on the model of Montero, the intermediate shaft has to be disengaged from the steering gear. Remove the power steering fluid, and unbolt the pressure line fittings; supporting the engine/transaxle assembly and subframe with hydraulic jacks. Bolt securing the engine to the subframe, and subframe to the vehicle frame should be undone and the subframe lowered slightly to allow removal of the LB sway bar assembly and examination of the condition of the clamp bushes. Installation involves the opposite of what is required in removal in regard to fasteners, where all has to be tightened. At long last, fix the wheel and lugs and then lower the vehicle and uniformly tighten lugs to their required torque.