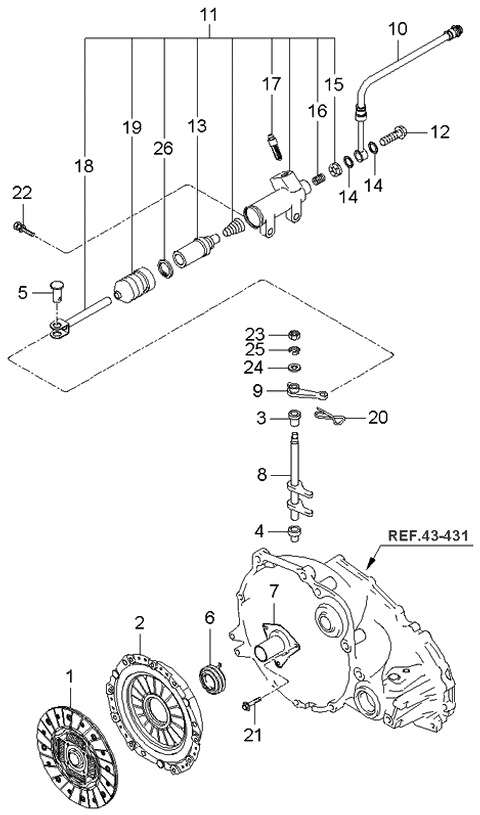

If, for some reason, you need to totally separate the transaxle from the vehicle here is how you can do it, To inspect, grasp the center of the bearing and apply force on it as you turn the outer portion; it should not be rough or noisy, if it is, replace it. Dry the bearing with a piece of clean cloth and also look underneath the bearing for signs of damage, cavities and cracks It should not be immerged in solvent as is a sealed bearing for life. Al so, check the release fork for wear, cracks and round for spap-ring retention groove wear, discoloration and missing metal. For installation, a little high temperature grease is to be applied at the internal region of the release bearing as well as at the portion where the fork fingers interact with it. Mount the bearing on the input shaft of the transaxle such that it interlocks with the fork fingers & lubricate the input shaft surface on which the bearing slides over with grease. For models from 2001 to 2006, lift the transaxle to the installation position near the engine, then install the release lever onto the fork shaft using the clevis pin and cotter pin, with the cylinder. Secure the transaxle to the engine, while pushing the release lever in a backward position, therapeutize the lever approximately 16 degrees you will hear the snap ring click, if it does not Click start again. In normal usage, the release lever should not move more than about 3 degrees; if it does, this will largely guarantee that engagement of the bearing is not on the pressure plate. For models from 2006.5 and later, combine the release bearing with the transaxle and the engine, as is done when fitting in the direct sense-in essence, the process of installation is the reversal of the process of removal.

Posted by KiaPartsNow Specialist