×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sorento CV Boot

Axle Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

39 CV Boots found

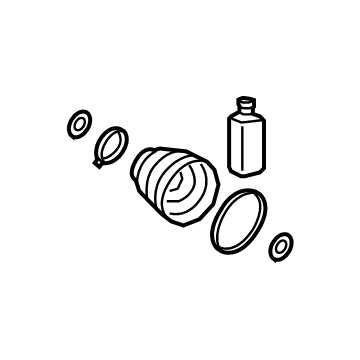

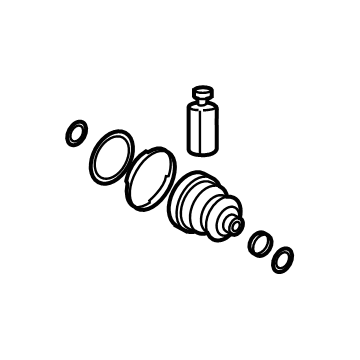

Kia Sorento Boot Kit-Front Axle Differential

Part Number: 49583C5050$84.72 MSRP: $122.25You Save: $37.53 (31%)

Kia Sorento Boot Kit-Front Axle Differential

Part Number: 496061UA00$63.69 MSRP: $91.90You Save: $28.21 (31%)Ships in 1-3 Business Days

Kia Sorento Boot Kit-Front Axle Differential

Part Number: 49583C5200$4.75 MSRP: $6.80You Save: $2.05 (31%)Ships in 1-3 Business Days

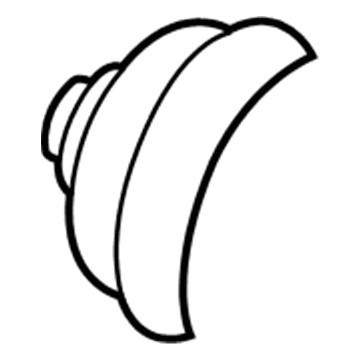

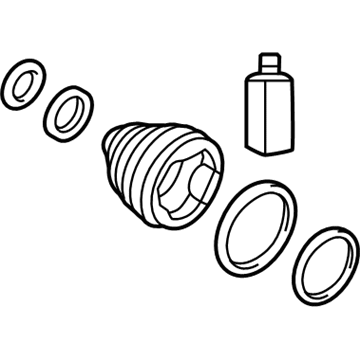

Kia Sorento Boot Kit-Front Axle Wheel

Part Number: 495812W600$4.75 MSRP: $6.80You Save: $2.05 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 49581C5080$72.67 MSRP: $104.87You Save: $32.20 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 49583C5130$4.75 MSRP: $6.80You Save: $2.05 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

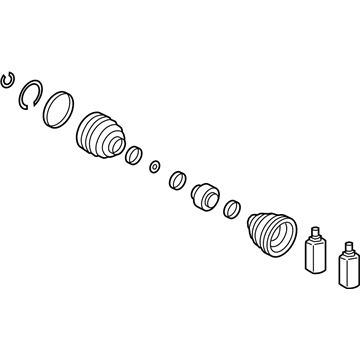

Part Number: 495812W200$379.58 MSRP: $555.92You Save: $176.34 (32%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle

Part Number: 495832W100$86.56 MSRP: $124.90You Save: $38.34 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 495832W200$91.13 MSRP: $131.50You Save: $40.37 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 49583C5100$86.56 MSRP: $124.90You Save: $38.34 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 495812W400$379.58 MSRP: $555.92You Save: $176.34 (32%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 49581C5130$72.67 MSRP: $104.87You Save: $32.20 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Rear Axle Differential

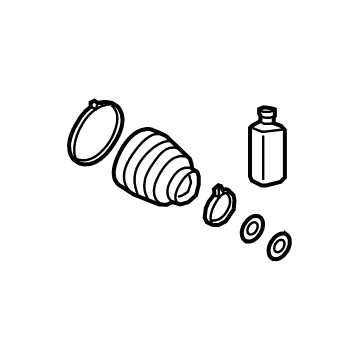

Part Number: 495061UA60$157.51 MSRP: $229.27You Save: $71.76 (32%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 496091UA10$95.83 MSRP: $138.28You Save: $42.45 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 495832W650$112.52 MSRP: $153.72You Save: $41.20 (27%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 49581C5050$131.39 MSRP: $191.25You Save: $59.86 (32%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 496061UA10$69.18 MSRP: $99.83You Save: $30.65 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Differential

Part Number: 49583C5250$93.20 MSRP: $134.48You Save: $41.28 (31%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 49581C5200$123.04 MSRP: $179.10You Save: $56.06 (32%)Ships in 1-3 Business DaysKia Sorento Boot Kit-Front Axle Wheel

Part Number: 495814Z600$310.45 MSRP: $454.67You Save: $144.22 (32%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 39 Results

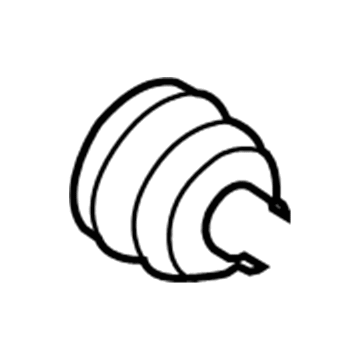

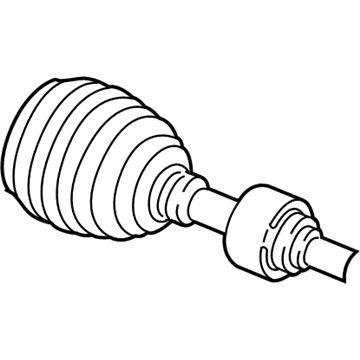

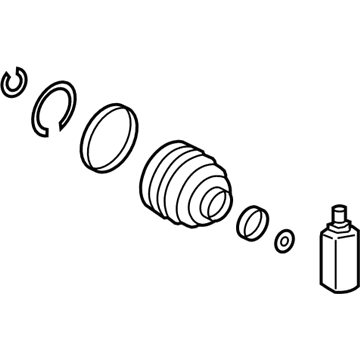

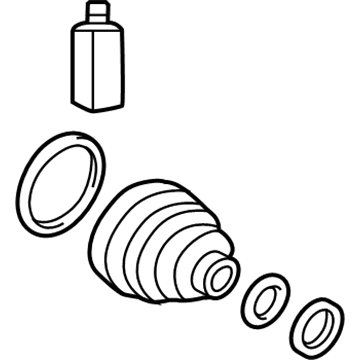

Kia Sorento CV Boot

The Kia Sorento CV Boot is a crucial part of automobile that directly impacts with the efficiency and durability of the Kia Sorento models. Specifically meant for shielding the constant velocity (CV) joint, the CV Boot helps in transmitting power from the transaxle to the wheels thus proving extremely important for the general efficiency and safety of the automobile. Since the assembly of the Kia Sorento began in 2002, it even went through several models, and the CV Boot fits them all: from the first generation, suitable for off-road, to the fourth generation, which is loaded with high technologies. This sort of flexibility show the Kia Sorento car's resilience and fitness for the work it was designed for. The CV Boot, usually fabricated with materials like flexible rubber or plastic contains lubricant for the joints without which the boot protects from external harm which is crucial in averting CV joint's failure. Valve boss sealing and CV Boot should be checked for any signs of wear including splits or even breaks to enhance the durability of Kia Sorento's performance. Remarkably, Kia Sorento CV Boot can be considered as unique in the given market segment because of its reliable construction and the importance of its function as the safety and performance booster. The Kia Sorento is still among consumers' favorites because of its reliable features, and the CV Boot acts as a vital component of this fantastic mid-size crossover SUV.

If you're in search of top-notch, reasonably priced OEM Kia Sorento CV Boot, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sorento CV Boot, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sorento CV Boot Parts Questions & Experts Answers

- Q: What should you consider before replacing CV joint boots on Kia Sorento?A:If the CV joint boots needs to be replaced, time should be taken to see that all options are the best because complete rebuilt CV Boots are available for exchange. It is recommended that the cost and availability of the parts to be removed should be determined before disassembly. The procedure applies to a tripod-type inner joint and for the sake of checking adequacy of cleaning every joint has similar steps. The starting point is the removal of the CV Boot which has to be clamped in a vise using wood protected jaws so as not to harm the part. Check the amount of radial float on the CV joint and its movement as it needs to roll smoothly. If a boot is torn, dismantle, the joint and clean the separated parts to determine if they were damaged from the effects of lubrication or contamination. Unbolt the rods using a flat-head screwdriver and separate the outer boot from the CV joint using scissors if the prior boot has worn out. Remove the inner CV joint boot completely and take the housing backwards by pulling it, if there is a wire ring retainer then eliminate it. Heat the part so it will be easy to disassemble then rebuff the tripod and axleshaft for reassembly then remove the tripod joint snap-ring using snap-ring pliers. A hammer and a brass punch can be used for tightening the tripod joint from the CV Boot being careful not to harm bearing surfaces or splines. Wipe all parts with solvent and look for signs of wear or damage of any of the components. If the inner CV joint is worn, only the new inner CV joint can be put on the old axleshaft, if the outer CV joint is worn then both an outer joint and axleshaft must be bought. To reassemble, ensure that the splines on the inner end of the shaft are covered by tape to protect the boots, then, slide the end clamps and boot on the axleshaft followed by placing the tripod on the shaft. Grease should be given to the tripod assembly and inside casing, for the tripod to fit in this casing, grease around it. Set the boot again into the grooves properly, check and confirm that the length of the CV Boot is acceptable to be fixed now, balance the pressure within the boot and finally put in the clamps. Last of all, places the CV Boot assembly.