×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

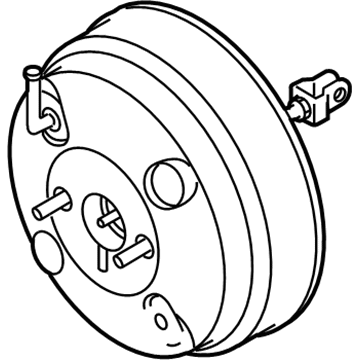

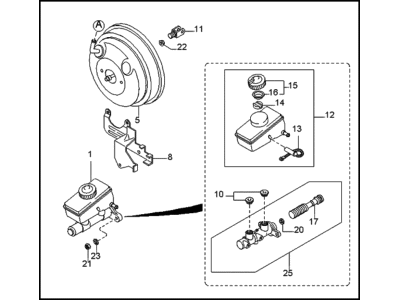

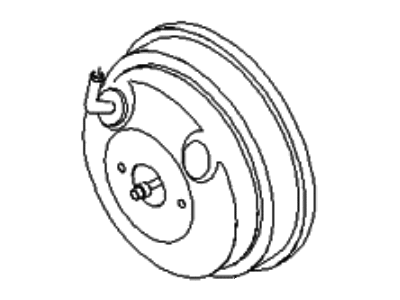

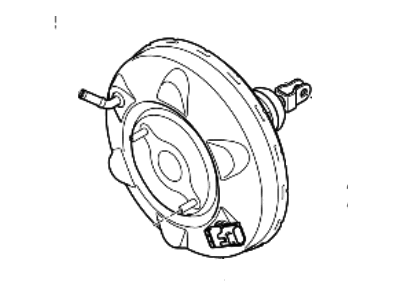

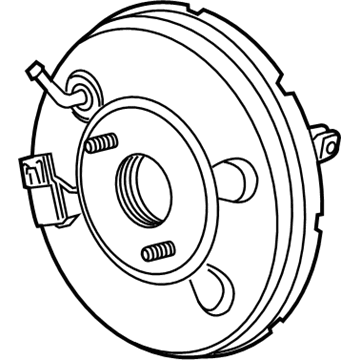

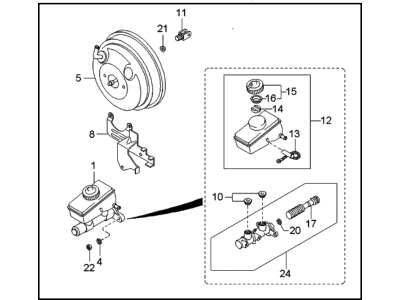

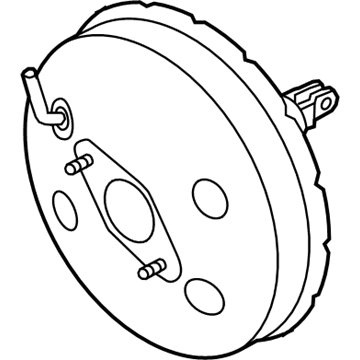

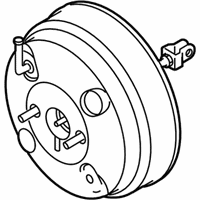

Genuine Kia Sportage Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Brake Boosters found

Kia Sportage Booster Assembly-Brake

Part Number: 591102E200$414.25 MSRP: $606.70You Save: $192.45 (32%)Ships in 1-3 Business DaysKia Sportage Master Vac Assembly

Part Number: 0K08143950$432.19 MSRP: $607.87You Save: $175.68 (29%)Ships in 1-3 Business DaysKia Sportage Master VACUMM Assembly

Part Number: 0K08043950B$434.44 MSRP: $636.27You Save: $201.83 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08B43950$458.14 MSRP: $644.37You Save: $186.23 (29%)Ships in 1-3 Business DaysKia Sportage Master Vacuum

Part Number: 0K08A43800$367.11 MSRP: $537.65You Save: $170.54 (32%)Ships in 1-3 Business DaysKia Sportage BOOSTER ASSY-BRAKE

Part Number: 59110CW200$199.88 MSRP: $290.95You Save: $91.07 (32%)Ships in 1-3 Business DaysKia Sportage Booster Assembly-Brake

Part Number: 59110D9200$470.75 MSRP: $694.32You Save: $223.57 (33%)Kia Sportage Master Vacuum

Part Number: 0K08043800$367.11 MSRP: $537.65You Save: $170.54 (32%)Ships in 1-3 Business DaysKia Sportage Master VACUMM Assembly

Part Number: 0K08A43950B$409.57 MSRP: $576.05You Save: $166.48 (29%)Ships in 1-3 Business DaysKia Sportage Master Vacuum Assembly

Part Number: 0K08A43950C$393.33 MSRP: $576.05You Save: $182.72 (32%)Ships in 1-3 Business DaysKia Sportage Master Vacuum Assembly

Part Number: 0K08B43950C$409.57 MSRP: $576.05You Save: $166.48 (29%)Ships in 1-3 Business DaysKia Sportage Master Vacuum Assembly

Part Number: 0K08B43950D$393.33 MSRP: $576.05You Save: $182.72 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08A43950$410.97 MSRP: $601.88You Save: $190.91 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08A43950A$410.97 MSRP: $601.88You Save: $190.91 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08B43950B$410.97 MSRP: $601.88You Save: $190.91 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08143950A$415.05 MSRP: $607.87You Save: $192.82 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08143950B$416.79 MSRP: $610.42You Save: $193.63 (32%)Ships in 1-3 Business DaysKia Sportage Booster Assembly-Brake

Part Number: 591103W000$434.28 MSRP: $636.03You Save: $201.75 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08B43950A$439.97 MSRP: $644.37You Save: $204.40 (32%)Ships in 1-3 Business DaysKia Sportage Master VACASSY

Part Number: 0K08043950$442.90 MSRP: $648.65You Save: $205.75 (32%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

Kia Sportage Brake Booster

If you're in search of top-notch, reasonably priced OEM Kia Sportage Brake Booster, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sportage Brake Booster, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sportage Brake Booster Parts Questions & Experts Answers

- Q: How to Inspect and Maintain Brake Systems and Brake Booster on Kia Sportage?A:Brake inspections should be done after a specified period of time and they should also be frequently carried out whenever wheels are removed or when any brake system defect is suspected.Brake pulling to one side, squealing or dragging brake noises, excessive travel on the brake pedal, pulsation in the pedal, and leakages of the brake fluid warn a driver about his/her brake system Disc brakes can be assessed visually through removing hub caps, loosening wheel lug nuts, jacking up the vehicle with a jackstand and remove the wheels giving access to disc brake caliper and pads.Inspect both inner and outer wear pads comparing measurements with specified limits. Replace once it goes below. Also inspect the disc for worn spots, score marks or burnt spots wherein it will require servicing or replacement if these are noticed. Brake lines and hoses need to be examined for signs of damage, wear and leaks before wheel installation.For rear drum models of drum brakes tap their drums to free them by making sure that parking brake is off.Spray cleaner on all parts of the brake assembly including shoes' lining thickness at front and back which will have to be replaced in case it falls below required limit or show indications for damage or fluid contamination.Ensure all springs related to the assembly are intact as well as inspect whether there are any fluid leakage especially in a wheel cylinder.If necessary clean interior part of drum looking out for imperfections then take another set of wheels into consideration.The operation capability of a booster can be tested following certain steps whereas proper adjustment of parking brakes can either involve counting clicks during slow application or testing on steep slope so as to prevent rolling away.

Related Kia Sportage Parts

Browse by Year

2024 Brake Booster 2023 Brake Booster 2022 Brake Booster 2021 Brake Booster 2020 Brake Booster 2019 Brake Booster 2018 Brake Booster 2017 Brake Booster 2016 Brake Booster 2015 Brake Booster 2014 Brake Booster 2013 Brake Booster 2012 Brake Booster 2011 Brake Booster 2010 Brake Booster 2009 Brake Booster 2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster