×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

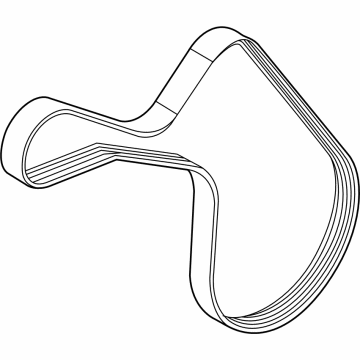

Genuine Kia Sportage Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Drive Belts found

Kia Sportage Drive Fan Belt V-Ribbed Belt

Part Number: 252122G760$37.34 MSRP: $53.89You Save: $16.55 (31%)Ships in 1-2 Business Days

Kia Sportage V Belt

Part Number: 252122GGB0$32.59 MSRP: $47.04You Save: $14.45 (31%)Ships in 1-3 Business Days

Kia Sportage V Ribbed Belt

Part Number: 252122G710$32.59 MSRP: $47.04You Save: $14.45 (31%)Ships in 1-3 Business Days

Kia Sportage Power Steering Pump V Belt

Part Number: 571702D101$22.86 MSRP: $32.70You Save: $9.84 (31%)Ships in 1-3 Business Days

Kia Sportage V Ribbed Belt

Part Number: 2521223721$22.83 MSRP: $32.67You Save: $9.84 (31%)Ships in 1 Business Day

Kia Sportage V Ribbed Belt

Part Number: 2521223700$24.11 MSRP: $32.67You Save: $8.56 (27%)Ships in 1-3 Business Days

Kia Sportage V Belt

Part Number: 977132D510$22.82 MSRP: $32.65You Save: $9.83 (31%)Ships in 1 Business Day

Kia Sportage V-Ribbed Belt

Part Number: 2521237182$31.15 MSRP: $44.95You Save: $13.80 (31%)Ships in 1-3 Business DaysKia Sportage V Belt

Part Number: 0K65B15907C$22.50 MSRP: $32.18You Save: $9.68 (31%)Ships in 1-3 Business Days

Kia Sportage V Belt

Part Number: 0K01118381A$23.75 MSRP: $32.18You Save: $8.43 (27%)Ships in 1-3 Business DaysKia Sportage RIBBED Belt-V

Part Number: 252122S000$29.64 MSRP: $42.77You Save: $13.13 (31%)Ships in 1-3 Business DaysKia Sportage Serpentine Belt

Part Number: 2521237162$31.15 MSRP: $44.95You Save: $13.80 (31%)Ships in 1-3 Business DaysKia Sportage V Belt

Part Number: 0K55215909$31.31 MSRP: $42.77You Save: $11.46 (27%)Ships in 1-3 Business DaysKia Sportage RIBBED Belt-V

Part Number: 252122MHA0$34.71 MSRP: $50.09You Save: $15.38 (31%)Ships in 1-3 Business DaysKia Sportage V Ribbed Belt

Part Number: 2521237181$32.90 MSRP: $44.95You Save: $12.05 (27%)Ships in 1-3 Business Days

Kia Sportage Drive Belt

If you're in search of top-notch, reasonably priced OEM Kia Sportage Drive Belt, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sportage Drive Belt, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sportage Drive Belt Parts Questions & Experts Answers

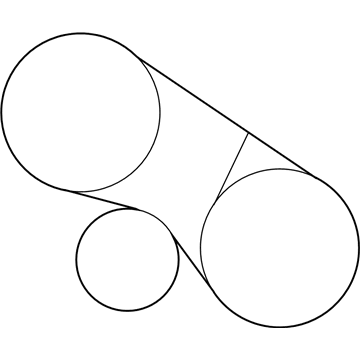

- Q: How to inspect and adjust drivebelts in a Kia Sportage?A:Situated in front of the engine, drivebelts are vital elements that need regular scrutiny and correction to prevent possible destruction. These are the ones which run the alternator, power steering pump, air conditioning compressor (if equipped), and water pump with two belts for each. While inspecting these belts for cracks, gaps in between them, thread separation, glazing or rib uniformity when the engine is off, it is important to visually observe their condition. Tension can be determined by applying a downward force of 20 pounds at the belt's midpoint when one wants to measure its deflection. In order to achieve correct tension levels, pivot bolds should be loosened and adjuster used for shifting parts. New belts are put into position after removal of adjustment, sliding off worn ones and installing new ones accordingly. V6 models have a single belt held under tension by an automatic spring-loaded adjuster. Inspections are done similarly because if the tensioner arm moves beyond marks set due to stretching belts it means they have to be replaced instead. For V6 models on the other hand, replacing this drivebelt entails identifying its routing system as well as rotating tensioner pulley arm until old belt is removed thereby allowing installation of new one respectively. Lastly, remove drivebelt followed by removal of tensioner mounting bolt before replacing it using reverse procedure including installing new ones into place.

Related Kia Sportage Parts

Browse by Year

2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt