×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sportage PCV Hose

PCV Valve Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 PCV Hoses found

Kia Sportage Hose Assembly-PCV

Part Number: 267202G751$21.17 MSRP: $28.68You Save: $7.51 (27%)Ships in 1-3 Business Days

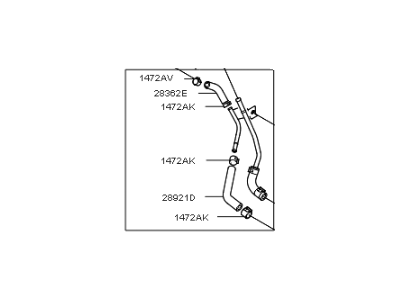

Kia Sportage Pipe & Hose Assembly-PCV

Part Number: 289312G700$54.31 MSRP: $74.20You Save: $19.89 (27%)Ships in 1-3 Business Days

Kia Sportage Hose Assembly-PCV

Part Number: 267202G761$16.34 MSRP: $23.38You Save: $7.04 (31%)Ships in 1-3 Business Days

Kia Sportage Hose Assembly-PCV

Part Number: 267202G000$20.77 MSRP: $29.72You Save: $8.95 (31%)Ships in 1-3 Business Days

Kia Sportage Hose Assembly-PCV

Part Number: 267202GTA0$27.11 MSRP: $38.78You Save: $11.67 (31%)Ships in 1-3 Business DaysKia Sportage Hose Assembly-PCV

Part Number: 267202GGA0$34.43 MSRP: $49.68You Save: $15.25 (31%)Ships in 1-3 Business DaysKia Sportage Hose-PCV

Part Number: 2672137281$10.50 MSRP: $14.23You Save: $3.73 (27%)Ships in 1-3 Business DaysKia Sportage Pipe & Hose Assembly-PCV

Part Number: 289312G090$54.81 MSRP: $74.88You Save: $20.07 (27%)Ships in 1-3 Business DaysKia Sportage Hose Assembly-PCV

Part Number: 267202G760$17.26 MSRP: $23.38You Save: $6.12 (27%)Ships in 1-3 Business DaysKia Sportage Pipe & Hose Assembly-PCV

Part Number: 289312G080$54.81 MSRP: $74.88You Save: $20.07 (27%)Ships in 1-3 Business DaysKia Sportage Pipe & Hose Assembly-PCV

Part Number: 289312GGB6$57.34 MSRP: $78.33You Save: $20.99 (27%)Ships in 1-3 Business DaysKia Sportage Hose Assembly-PCSV

Part Number: 31341P0000$33.17 MSRP: $45.32You Save: $12.15 (27%)Ships in 1-3 Business DaysKia Sportage Hose Assembly-PCV

Part Number: 267202GTA2$43.87 MSRP: $59.93You Save: $16.06 (27%)Ships in 1-3 Business Days

Kia Sportage PCV Hose

If you're in search of top-notch, reasonably priced OEM Kia Sportage PCV Hose, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sportage PCV Hose, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sportage PCV Hose Parts Questions & Experts Answers

- Q: How to inspect and replace PCV Hose, rubber and plastic hoses in the engine, accessory, and emission systems on Kia Sportage?A:The high temperatures under the hood, therefore, demand that rubber and plastic hoses be inspected regularly in the engine, accessory and emission systems to prevent deterioration. Material hardening ,leaks,crracks and looseness of clips should be sought for. Since most hoses are clamped they should always be kept in tension all time so that no leaks can occur .In addition there is need to check hoses without clamps as they may expand or harden thus potentially causing leakage.To avoid destructions by obstructions and damage it needs to be checked for this.Whereas vacuum hoses which usually have various color codes for identification are variable in wall thickness, collapse resistance and temperature resistance among others.Vacuum hoses should be replaced with ones of similar composition. Plastic t-fittings attached with these lines are likely to crack or deform .One only requires a few inches of a vacuum hose which can serve as a stethoscope of sorts by listening for any hissing sounds that accompany a vacuum leak.Vigilance is necessary when handling fuel hoses operating under pressure to determine their condition prior to installation as well as replacement since they are prone to chafing and cracking because of their current state.Spring type fasteners should not be used again on changing the hose but screw fasteners.Discover if metal tubes made from elongated steel pipes are bent broken or folded. If you have to replace them use seamless steel tubing instead .It also adds up that brake fluid will seep through when there is leaking in-between the lines posing great risks.

Related Kia Sportage Parts

Browse by Year

2024 PCV Hose 2023 PCV Hose 2022 PCV Hose 2021 PCV Hose 2020 PCV Hose 2019 PCV Hose 2018 PCV Hose 2017 PCV Hose 2016 PCV Hose 2015 PCV Hose 2014 PCV Hose 2013 PCV Hose 2012 PCV Hose 2011 PCV Hose 2010 PCV Hose 2009 PCV Hose 2008 PCV Hose 2007 PCV Hose 2006 PCV Hose 2005 PCV Hose 2002 PCV Hose 2001 PCV Hose 2000 PCV Hose 1999 PCV Hose 1998 PCV Hose 1997 PCV Hose