×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Optima Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Drive Belts found

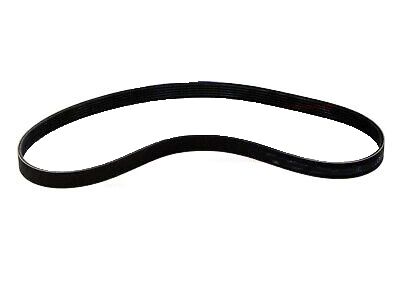

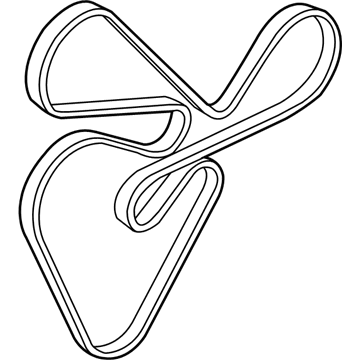

Kia Optima Drive Fan Belt V-Ribbed Belt

Part Number: 252122G760$37.34 MSRP: $53.89You Save: $16.55 (31%)Ships in 1-2 Business Days

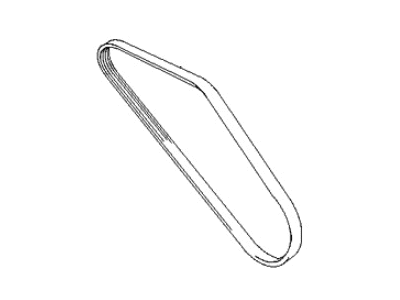

Kia Optima V Belt

Part Number: 252122GGB0$32.59 MSRP: $47.04You Save: $14.45 (31%)Ships in 1-3 Business Days

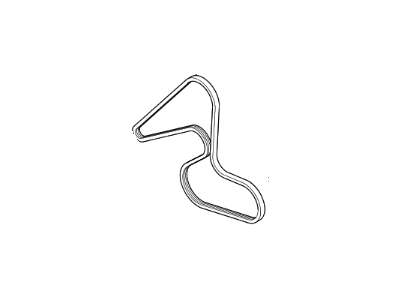

Kia Optima V Ribbed Belt

Part Number: 252122G710$32.59 MSRP: $47.04You Save: $14.45 (31%)Ships in 1-3 Business Days

Kia Optima V-Ribbed Belt

Part Number: 2521225000$36.84 MSRP: $53.17You Save: $16.33 (31%)Ships in 1-3 Business Days

Kia Optima V Belt

Part Number: 252122B720$30.21 MSRP: $43.60You Save: $13.39 (31%)Ships in 1-2 Business Days

Kia Optima V Ribbed Belt

Part Number: 2521238001$22.15 MSRP: $31.69You Save: $9.54 (31%)Ships in 1-3 Business Days

Kia Optima V-Ribbed Belt

Part Number: 252123E000$32.85 MSRP: $44.89You Save: $12.04 (27%)Ships in 1-3 Business DaysKia Optima V Ribbed Belt

Part Number: 2521225020$37.01 MSRP: $53.40You Save: $16.39 (31%)Ships in 1-3 Business DaysKia Optima V Ribbed Belt

Part Number: 2521237110$31.93 MSRP: $43.62You Save: $11.69 (27%)Ships in 1-3 Business DaysKia Optima Serpentine V-Ribbed Belt

Part Number: 2521237111$31.93 MSRP: $43.62You Save: $11.69 (27%)Ships in 1-3 Business DaysKia Optima V Ribbed Belt

Part Number: 2521237181$31.94 MSRP: $43.64You Save: $11.70 (27%)Ships in 1-3 Business Days

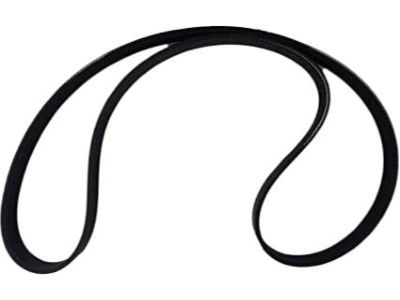

Kia Optima Drive Belt

If you're in search of top-notch, reasonably priced OEM Kia Optima Drive Belt, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Optima Drive Belt, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Optima Drive Belt Parts Questions & Experts Answers

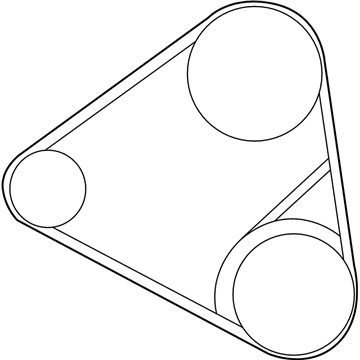

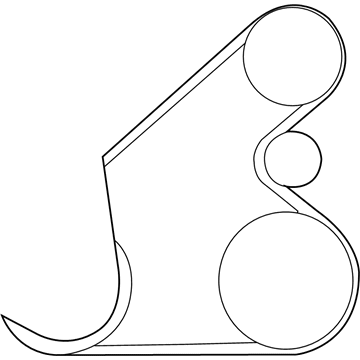

- Q: What is the importance of inspecting and maintaining drivebelts on Kia Optima?A:The drivebelt(s) are located at the front of the engine, and their good condition and proper adjustment are critical to engine operation. Due to their composition and the high stresses they endure, drivebelts stretch and deteriorate over time, necessitating periodic inspection. With the engine off, open the hood and locate the drivebelts, using a flashlight to check for separation of the adhesive rubber, core separation, severed cores, cracking, or worn ribs. Inspect both sides of the belt by twisting it to check the underside and feeling for any damage. For four-cylinder engines from 2001 to 2006, check the tension by pushing on the belt halfway between the pulleys; it should deflect approximately 1/4-inch, while other models have a self-adjusting tensioner. To adjust the alternator belt, loosen the lower mounting bolt and upper tension bolts, then carefully tension the belt and tighten the bolts. For power steering pump and air conditioning compressor belts, loosen the lock bolt on the tensioner assembly and adjust the tension using the adjacent bolt before tightening the lock bolt. When replacing belts, remove any interfering components, release tension, and slip the belt off the pulleys. For engines with a self-adjusting tensioner, use a breaker bar to release tension before removing the belt. Always take the old belt to the parts store for comparison and ensure the new belt fits properly in the ribbed grooves of the pulleys, adjusting as necessary. It is advisable to replace both belts simultaneously if they tend to wear out together, marking each belt and its corresponding pulley groove for proper installation.

Related Kia Optima Parts

Browse by Year

2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt