×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

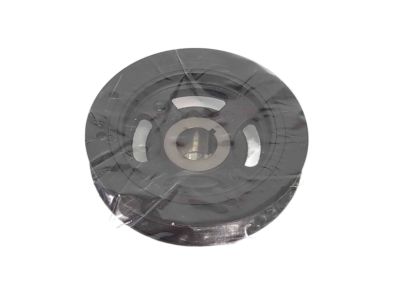

Genuine Kia Optima Crankshaft Pulley

Crankshaft Pulley Engine Harmonic Balancer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Crankshaft Pulleys found

Kia Optima PULLEY-DAMPER

Part Number: 231242G600$114.76 MSRP: $167.05You Save: $52.29 (32%)Ships in 1-2 Business Days

Kia Optima PULLEY-DAMPER

Part Number: 2312425000$128.39 MSRP: $178.32You Save: $49.93 (28%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231242GGA0$117.06 MSRP: $170.40You Save: $53.34 (32%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231232B720$115.77 MSRP: $168.52You Save: $52.75 (32%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231243E020$168.61 MSRP: $245.43You Save: $76.82 (32%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231242G000$120.28 MSRP: $167.05You Save: $46.77 (28%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231243E010$176.71 MSRP: $245.43You Save: $68.72 (28%)Ships in 1-2 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231243E021$172.67 MSRP: $239.82You Save: $67.15 (28%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 2312438201$190.06 MSRP: $263.97You Save: $73.91 (28%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 231242GGA1$122.69 MSRP: $170.40You Save: $47.71 (28%)Ships in 1-3 Business DaysKia Optima PULLEY-DAMPER

Part Number: 2312437500$162.55 MSRP: $225.77You Save: $63.22 (28%)Ships in 1-3 Business Days

Kia Optima Crankshaft Pulley

If you're in search of top-notch, reasonably priced OEM Kia Optima Crankshaft Pulley, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Optima Crankshaft Pulley, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Optima Crankshaft Pulley Parts Questions & Experts Answers

- Q: How to remove and insatll the Crankshaft Pulley on Kia Optima?A:This procedure also applies to the V6 engines, so be sure to use the bolt torque specification when working on a V6 engine. Begin by disconnecting the cable from the negative terminal of the battery. Next, remove the drivebelt. With the parking brake applied and the shifter in Park (automatic) or in gear (manual), loosen the lug nuts from the right front wheel, then raise the front of the vehicle and support it securely on jackstands. Remove the engine splash shield, the front wheel, and the splash shield from the right wheel well. Proceed to remove all other interfering components specific to your vehicle. Then, remove the bolt from the front of the crankshaft; if an impact wrench is unavailable, lock the Flywheel with a large screwdriver to prevent the crankshaft from turning while loosening the bolt, using a breaker bar as necessary due to the tightness of the bolt. An assistant should lock the flywheel in place with a prybar inserted into the ring gear, which may require removing the flywheel/driveplate access cover. Using a puller that grasps the crankshaft hub, remove the crankshaft pulley, ensuring not to use a jaw-type puller that could damage the pulley/damper assembly, and use the proper adapter to prevent damage to the crankshaft end. The pulley may sometimes be removable by hand, so attempt to pull it straight off before using the puller. For installation, slide the pulley onto the crankshaft as far as it will go; if removed by hand, install the bolt and washer and tighten it to the specified torque. If a puller was used, employ a vibration damper installation tool to press the pulley onto the crankshaft, then install the bolt and washer and tighten it to the specified torque, ensuring the slot in the hub aligns with the Woodruff key in the crankshaft end. Finally, complete the remaining installation steps in reverse order of removal.

Related Kia Optima Parts

Browse by Year

2020 Crankshaft Pulley 2019 Crankshaft Pulley 2018 Crankshaft Pulley 2017 Crankshaft Pulley 2016 Crankshaft Pulley 2015 Crankshaft Pulley 2014 Crankshaft Pulley 2013 Crankshaft Pulley 2012 Crankshaft Pulley 2011 Crankshaft Pulley 2010 Crankshaft Pulley 2009 Crankshaft Pulley 2008 Crankshaft Pulley 2007 Crankshaft Pulley 2006 Crankshaft Pulley 2005 Crankshaft Pulley 2004 Crankshaft Pulley 2003 Crankshaft Pulley 2002 Crankshaft Pulley 2001 Crankshaft Pulley 2000 Crankshaft Pulley