×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Optima Spark Plug Wire

Spark Plug Ignition Wires- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Spark Plug Wires found

Kia Optima Ignition Coiling Harness

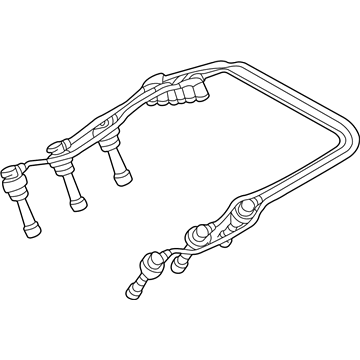

Part Number: 396103E600$77.79 MSRP: $112.25You Save: $34.46 (31%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.1

Part Number: 2742037101$22.14 MSRP: $30.00You Save: $7.86 (27%)Ships in 1-3 Business DaysKia Optima Ignition Coiling Harness

Part Number: 396103E100$34.25 MSRP: $49.42You Save: $15.17 (31%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.2

Part Number: 2743037101$17.76 MSRP: $24.07You Save: $6.31 (27%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.4

Part Number: 2745037101$17.76 MSRP: $24.07You Save: $6.31 (27%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.5

Part Number: 2746037101$17.22 MSRP: $23.34You Save: $6.12 (27%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.6

Part Number: 2747037101$17.75 MSRP: $24.05You Save: $6.30 (27%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.3

Part Number: 2744037101$22.14 MSRP: $30.00You Save: $7.86 (27%)Ships in 1-3 Business DaysKia Optima Spark Plug Cable Assembly No.1

Part Number: 2742038020$16.79 MSRP: $24.02You Save: $7.23 (31%)Ships in 1-3 Business Days

Kia Optima Spark Plug Wire

If you're in search of top-notch, reasonably priced OEM Kia Optima Spark Plug Wire, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Optima Spark Plug Wire, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Optima Spark Plug Wire Parts Questions & Experts Answers

- Q: How should spark plug wires be inspected and maintained on Kia Optima?A:Some models utilize an ignition coil mounted on each Spark Plug instead of spark plug wires. The spark plug wires should be checked whenever new spark plugs are installed. Begin by visually inspecting the spark plug wires while the engine is running in a darkened garage with adequate ventilation. Observe each plug wire carefully, avoiding contact with moving engine parts. If a break in the wire is present, arcing or a small spark will be visible at the damaged area, indicating the need for new wires; allow the engine to cool and check the ignition coil packs afterward. Inspect the spark plug wires one at a time to maintain the correct order for proper engine operation, using numbered labels or tape if necessary. To disconnect a plug wire, grasp the rubber boot, twist it half a turn, and pull it free without tugging on the wire itself. Check inside the boot for corrosion, which appears as a white crusty powder; light corrosion can be cleaned with a small wire brush, but heavily corroded wires should be replaced. Reattach the wire and boot to the spark plug, ensuring a tight fit; if it's loose, use pliers to crimp the metal connector inside the boot. Wipe the entire length of the wire with a clean rag to remove dirt and grease, then inspect for burns, cracks, and other damage, avoiding sharp bends that could break the conductor. Disconnect the wire from the ignition coil pack by pulling only on the rubber boot, checking for corrosion and ensuring a tight fit before reconnecting. Inspect all remaining spark plug wires to confirm they are securely fastened at both the coil pack and spark plug. If new spark plug wires are necessary, purchase a set specific to the engine model and replace them one at a time to prevent mix-ups in firing order. Clean the coil pack and spark plug wires with a damp cloth and dry them thoroughly, while also inspecting the coil pack for cracks, damage, and carbon tracking.