×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sedona Trailing Arm

Trailing Control Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Trailing Arms found

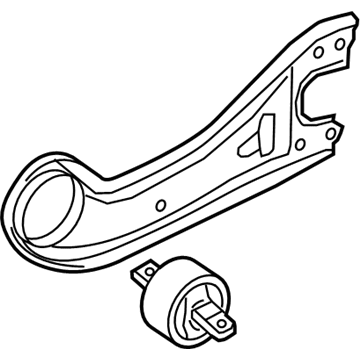

Kia Sedona Arm Assembly-Rear Trailing

Part Number: 55270A9100$119.00 MSRP: $162.57You Save: $43.57 (27%)Ships in 1-3 Business DaysKia Sedona Arm Complete-Trailing R

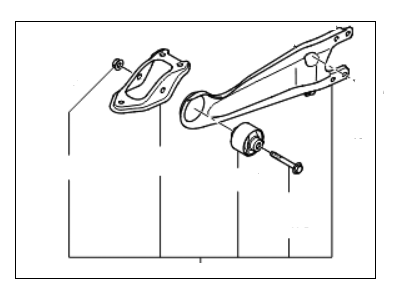

Part Number: 551014D000$317.45 MSRP: $464.92You Save: $147.47 (32%)Ships in 1-3 Business DaysKia Sedona Arm COML-Trailing,LH

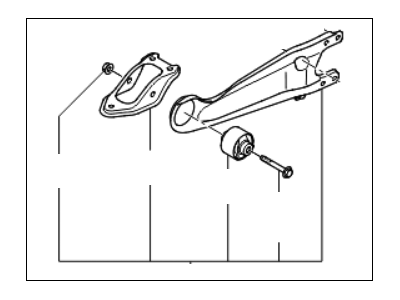

Part Number: 551004D000$238.87 MSRP: $349.83You Save: $110.96 (32%)Ships in 1-3 Business DaysKia Sedona Arm Assembly-Rear Trailing

Part Number: 55280A9100$120.32 MSRP: $167.12You Save: $46.80 (28%)Ships in 1-3 Business DaysKia Sedona Arm Complete-Trailing R

Part Number: 551014D200$330.56 MSRP: $464.92You Save: $134.36 (29%)Ships in 1-3 Business DaysKia Sedona Arm Complete-Trailing,L

Part Number: 551004D200$248.73 MSRP: $349.83You Save: $101.10 (29%)Ships in 1-3 Business DaysKia Sedona Arm Assembly-Rear Trailing

Part Number: 55270A9200$112.66 MSRP: $162.57You Save: $49.91 (31%)Ships in 1-3 Business DaysKia Sedona Arm Assembly-Rear Trailing

Part Number: 55280A9200$114.81 MSRP: $167.12You Save: $52.31 (32%)Ships in 1-3 Business DaysKia Sedona Arm Assembly-Lower , LH

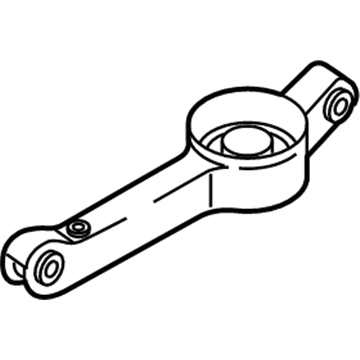

Part Number: 0K55328350B$233.04 MSRP: $341.30You Save: $108.26 (32%)Ships in 1-3 Business Days

Kia Sedona Trailing Arm

If you're in search of top-notch, reasonably priced OEM Kia Sedona Trailing Arm, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sedona Trailing Arm, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sedona Trailing Arm Parts Questions & Experts Answers

- Q: How to remove and install rear Axle Beam,Control Arm and Trailing Arm in Kia Sedona?A:Rear axle beam is standard only if the truck model is 2005 and prior. Relax the nuts on the rear wheel, and lift the rear part of the car using jack stands placing them under the unibody frame rails. Lift the rear of the car and, using a floor jack, position it so that it is supporting the rear axle beam nearest the arm you are going to take off. Remove the rear stabilizer bar link bolt being you from the front of the trailing arm and then unbolt the nuts and pivot bolts attaching the trailing arm and take it out. Examine the bushings which often wears out and degrades with time and if that is the case then one need to take the arm to an automotive machine shop so that the worn bushings are pulled out and brand new bushings inserted. Installation is the direct opposite of the removal process, and all the bolts and nuts are usually tightened to the applied torque. When fitting any rear suspension arm, slacken all bolts, set up the rear suspension at normal ride height and-align the arm, then finally torque up the bolts. Regarding the upper arm or Panhard rod, place the rear axle beam on a jack, remove the nuts and pivot bolts and examine the bushings. These modules should also be installed following the same procedure that was followed earlier. At the axle beam, first, take off the rear drum brake assemblies and then disconnect the brake hydraulic fluid line fitting followed by lowering the beam with the aid of the floor jack. For the vehicles produced after 2006, the procedure is also very similar to the situations described above, due to the fact that the owner has to loosen the rear wheel lug nuts, then lift the car and finally put off the rear wheel. Here on the upper control arm you should remove the rear brake caliper and disconnect the upper control arm from the subframe and inspect the bushing and Ball Joint for wearing. Installation on the other hand is a process that is the reverse of removal; every fastener must be tightened always to the correct torque. To reach the lower control arm you then have to take off the coil spring then detach the arm from the subframe to check how the bushing has worn out. The procedure of installation remains the same, though after its completion, there is a check for rear wheel alignment. For the lateral control arm, place the lower control arm on a lift, mark the position of the cam washer and follow the procedures of removal and installation while being very keen on the alignment. As for the trailing arm, support the rear suspension, cancel the stabilizer bar link, take out the bolts fixing the trailing arm and check the condition of the bush in question for weariness. Removal is the exact opposite of installation, making certain to loosen, then tighten all suspension fasteners and lug nuts to the recommended torque, do not adjust the nut/bolt on the trailing arm to bracket pivot until the lower control arm has been mock raised to normal ride height.

Related Kia Sedona Parts

Browse by Year

2021 Trailing Arm 2020 Trailing Arm 2019 Trailing Arm 2018 Trailing Arm 2017 Trailing Arm 2016 Trailing Arm 2015 Trailing Arm 2014 Trailing Arm 2013 Trailing Arm 2012 Trailing Arm 2011 Trailing Arm 2010 Trailing Arm 2009 Trailing Arm 2008 Trailing Arm 2007 Trailing Arm 2006 Trailing Arm 2005 Trailing Arm 2004 Trailing Arm 2003 Trailing Arm 2002 Trailing Arm 2001 Trailing Arm