×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Spectra Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Oil Pans found

Kia Spectra Pan Assembly-Engine Oil

Part Number: 2152023604$263.06 MSRP: $385.27You Save: $122.21 (32%)Ships in 1-3 Business DaysKia Spectra Pan Assembly-Engine Oil

Part Number: 2152023700$1.96 MSRP: $2.80You Save: $0.84 (30%)Ships in 1-3 Business DaysKia Spectra Pan Assembly-Engine Oil

Part Number: 215102Y010$147.95 MSRP: $215.35You Save: $67.40 (32%)Ships in 1-3 Business DaysKia Spectra Pan Assembly-Oil

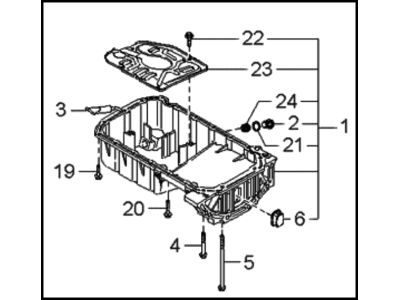

Part Number: 0K2N510400$172.28 MSRP: $250.77You Save: $78.49 (32%)Ships in 1-3 Business Days

Kia Spectra Oil Pan

If you're in search of top-notch, reasonably priced OEM Kia Spectra Oil Pan, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Spectra Oil Pan, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Spectra Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install the oil pan on Kia Spectra for four cylinder engine?A:Before removing the oil pan, refer to the battery's negative terminal, apply the parking brake and chock the rear wheels, and then lift front part of the car using jack stands. Pull out the engine splash plate(s), drain the engine oil and then, thence remove the oil cap. Remove the exhaust pipe from the Exhaust Manifold and the catalytic converter separate the exhaust pipe from the catalytic converter. Loosen the oil pan bolts and if present, the oil pan stiffener, with the information that oil pan bolts could be of different size. For 1.6L SOHC models: When disconnecting the oil pan stiffener, you would have to turn the stiffener upside down before removing the bolts of the stiffener.Continue removing all the bolts of the oil pan and the oil pan itself. However, if the oil pan is stuck, attempt to pry it free at the engine block ears. Remove the oil strainer from the oil pump and unscrew the MBSP bolts but do not mar the mating surfaces. On the 1.6L DOHC B6 and 1.8L DOHC T8 models, you should unscrew the two oil pan bolts, if you can't pry up the oil pan, use the chisel to loosen the bolts. Scrub all mating surfaces and check to make sure the threaded bolt holes in the block are clean. Inspection of the oil pan flange reveals indication of crack and or distortion. To some specific engine models, spread the RTV sealant where the main bearing-cap girders contact the engine block, and then put in the MBSP bolts, and fasten them in a proper pattern. Lubrication-for 1.6L DOHC B6 engines, fit the oil pan upper block and fasten the M6 x 1.0 bolts. Spread RTV sealant around the oil pan bolting flange, then place the oil pan onto the block of the engine and, finally, run bolts/nuts with an average torque in a staggered pattern starting in center. The process of installing is the exact opposite of the removal procedure whereby adequate oil is added, together with an oil filter. The RTV sealant should be allowed to dry for about 12 hours and then start the engine and examine for oil leaks.