×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sportage Starter Motor

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Starter motors found

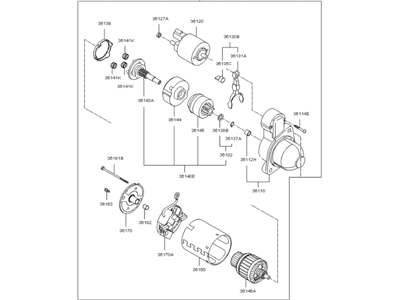

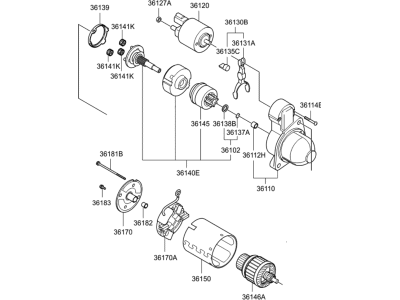

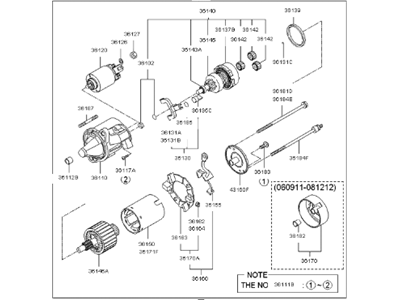

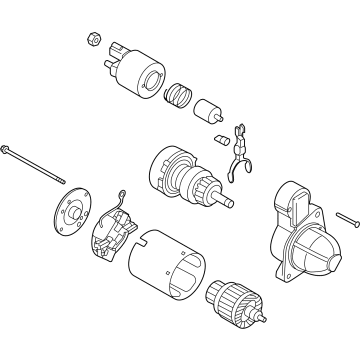

Kia Sportage Starter Assembly

Part Number: 361002G200$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business Days

Kia Sportage Starter Assembly

Part Number: 361002G300$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 3610037210$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assy

Part Number: 361002S010$274.27 MSRP: $401.68You Save: $127.41 (32%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 3610023170$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 361002G000$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 3610023070$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 3610023171$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business DaysKia Sportage Starter Assembly

Part Number: 3610023071$200.01 MSRP: $275.60You Save: $75.59 (28%)Ships in 1-3 Business Days

Kia Sportage Starter Motor

If you're in search of top-notch, reasonably priced OEM Kia Sportage Starter Motor, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sportage Starter Motor, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sportage Starter Motor Parts Questions & Experts Answers

- Q: How Do You Diagnose and Troubleshoot a Malfunctioning Starter Motor and Starting Circuit on Kia Sportage?A:In case of a starting circuit malfunction, begin by ensuring either the clutch pedal is depressed (for manual transaxle) or the shift lever is placed in PARK or NEUTRAL (for automatic transaxle). Make sure that Battery Cable clamps are clean and tight as well as inspecting battery cables for any that are damaged. Inspect the condition of the battery after testing it if it fails any tests and replace it. Also, check starter solenoid wiring and connections and ensure that starter mounting bolts are tight. Check engine compartment fuse box for burnt fuses; check ignition switch circuit; check operation of ignition switch circuit to be correct. Additionally, confirm manual transaxle's clutch start switch circuit or automatic transaxle's transaxle range switch circuit. If there is no action from starter when key on START position, verify battery voltage at solenoid "S" terminal to determine whether it receives proper signal from ignition switch. If none, consult wiring diagrams and inspect starter/ignition switch circuit fuse(s). If cranking speed appears slow this may indicate low voltage or excessive current draw; therefore terminals should be cleaned and the battery must meet specifications. If there is voltage but no engagement remove starter motor bench test using appropriate procedure remember crankshaft pulley may require rotating in some cases. On bench apply battery voltage to solenoid S terminal watch pinion drive; does drive come out without rotation-defective motor; does not start up although solenoid clicks-solenoid/starter motor could both be bad; plunger comes out while turning pinion drive-the assembly operates alright.

Related Kia Sportage Parts

Browse by Year

2024 Starter Motor 2023 Starter Motor 2022 Starter Motor 2021 Starter Motor 2020 Starter Motor 2019 Starter Motor 2018 Starter Motor 2017 Starter Motor 2016 Starter Motor 2015 Starter Motor 2014 Starter Motor 2013 Starter Motor 2012 Starter Motor 2011 Starter Motor 2010 Starter Motor 2009 Starter Motor 2008 Starter Motor 2007 Starter Motor 2006 Starter Motor 2005 Starter Motor