×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

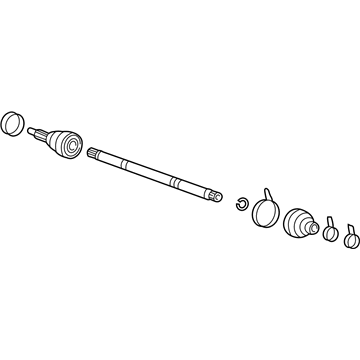

Genuine Kia Optima Axle Shaft

Car Axle Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

69 Axle Shafts found

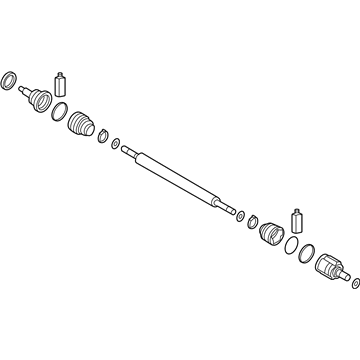

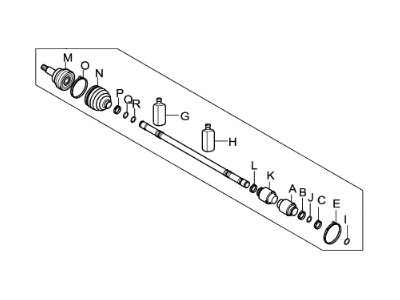

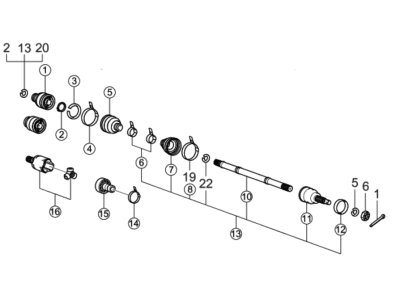

Kia Optima Shaft Assembly-Drive,LH

Part Number: 49500D4200$506.31 MSRP: $724.34You Save: $218.03 (31%)Ships in 1-3 Business Days

Kia Optima Shaft Assembly-Drive,RH

Part Number: 49501D4250$503.42 MSRP: $720.20You Save: $216.78 (31%)Ships in 1-3 Business Days

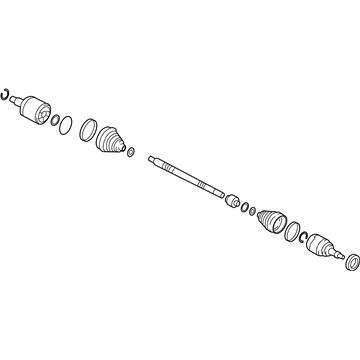

Kia Optima Joint Assembly-Cv RH

Part Number: 495013S350$505.85 MSRP: $723.68You Save: $217.83 (31%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495012G300$550.62 MSRP: $812.12You Save: $261.50 (33%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495003S300$485.50 MSRP: $694.57You Save: $209.07 (31%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495004C300$567.85 MSRP: $837.53You Save: $269.68 (33%)Ships in 1-3 Business Days

Kia Optima Shaft Assembly-Drive,LH

Part Number: 49500D4300$585.34 MSRP: $837.40You Save: $252.06 (31%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495004C301$567.76 MSRP: $837.40You Save: $269.64 (33%)Ships in 1-3 Business Days

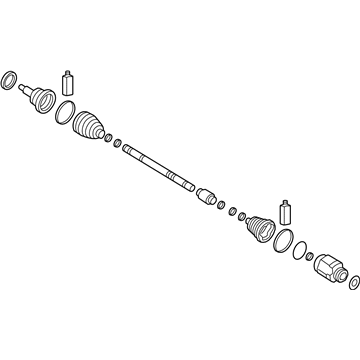

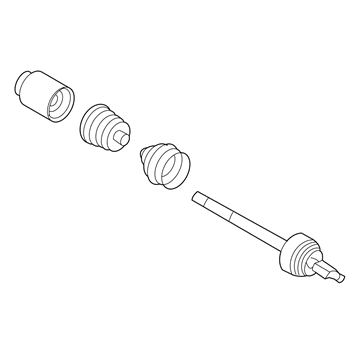

Kia Optima Joint & Shaft Kit-Front

Part Number: 495804C350$358.58 MSRP: $504.33You Save: $145.75 (29%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495004C700$567.76 MSRP: $837.40You Save: $269.64 (33%)Ships in 1-2 Business Days

Kia Optima Joint Assembly-Cv RH

Part Number: 495014C370$547.51 MSRP: $807.53You Save: $260.02 (33%)Ships in 1-3 Business Days

Kia Optima Shaft Assembly-Drive,RH

Part Number: 49501D4350$587.72 MSRP: $840.80You Save: $253.08 (31%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495004C320$554.43 MSRP: $817.75You Save: $263.32 (33%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv RH

Part Number: 495002G300$558.88 MSRP: $824.30You Save: $265.42 (33%)Ships in 1-3 Business Days

Kia Optima Joint Assembly-Cv LH

Part Number: 495002T700$465.79 MSRP: $655.12You Save: $189.33 (29%)Ships in 1-3 Business DaysKia Optima Shaft Assembly-Drive,LH

Part Number: 49500C2400$484.01 MSRP: $692.43You Save: $208.42 (31%)Ships in 1-3 Business DaysKia Optima Shaft Assembly-Drive,RH

Part Number: 49501D4450$587.72 MSRP: $840.80You Save: $253.08 (31%)Ships in 1-3 Business DaysKia Optima Joint Assembly-Cv LH

Part Number: 495012G500$550.62 MSRP: $812.12You Save: $261.50 (33%)Ships in 1-3 Business DaysKia Optima Shaft Assembly-Drive,LH

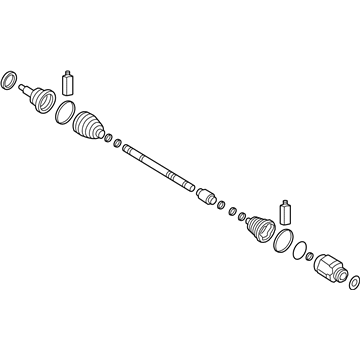

Part Number: 495003C442$585.34 MSRP: $837.40You Save: $252.06 (31%)Ships in 1-3 Business DaysKia Optima Joint Kit-Front Axle Shaft

Part Number: 4950838E00$312.86 MSRP: $458.20You Save: $145.34 (32%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 69 Results

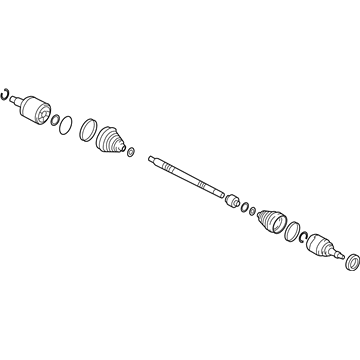

Kia Optima Axle Shaft

If you're in search of top-notch, reasonably priced OEM Kia Optima Axle Shaft, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Optima Axle Shaft, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Optima Axle Shaft Parts Questions & Experts Answers

- Q: How do you remove and install a driveaxle and wheel cover on Kia Optima?A:To take off the wheel cover or hub cap, first, one has to pull the cotter pin and also use a long breaker bar to loosen the axle shaft/hub nut then the wheel lug nuts. Loosen the wheel and then lift the vehicle and place it on stand before moving on to remove the wheel. Jack up both front wheels and set the parking brake on or drain the transaxle lubricant or place rags under the transaxle end of the axle shaft. Remove the electrical connector from the wheel speed sensor as well as the brake hose assembly mounting bolts. Cast off the outer tie-rod end from the steering knuckle; unbolt the two screws, which are on the lower balljoint but do not sever the joint. Pull the knuckle with the hub assembly out until the end of the axle shaft is clear from the hub, when the end of the axle shaft cannot be easily removed you can gently tap it with a plastic hammer, once the axle shaft is free from the hub and the knuckle is swung outwards use some wire to support the outer end so that does not exert pressure on the inner CV joint. To remove the axle shaft gently loosen the inner end of the axle shaft in the transaxle or center bearing support bracket with a large screwdriver prybar to support the CV joint. For intermediate shaft removal, replace the right axle shaft assembly, then undo the center bearing support bracket bolts and finally, the intermediate shaft can be pulled out from the transaxle. Check for any visible damages on the center bearing and if there is, then replace it. For installation, if it was removed reinstall the intermediate shaft; the old spring clip on the inner end of the axle shafts need to be replaced or renewed; apply lubrication for the differential or intermediate shaft seal and then lift the axle shafts into position while supporting the CV joints. Slide the splined end of the inner CV joint over the hollow shaft of the differential side gear with the spring clip snapping into place as the gap is down. Afterwards, use grease to apply it on the outer CV joint splines, pull out on the strut/steering knuckle assembly and then fit the stub axle into the hub. Engage the balljoint back to its position on the lower control arm and fasten the nuts to the required liveliness standard. Screw the axle shaft/hub nut with the convex surface of the washer laminated over the exposed threads of the nut ensuring that it is well seated, though without applying the actual torque until the car is raised. Check that the axle shaft is properly located in the transaxle by getting hold of the inner CV joint housing and applying a backward force. Lastly, there is the fitting of the wheel and the lug nuts followed by the lowering of the vehicle and then tightening of the lug nuts and axle shaft/hub nut to the recommended torque limit and a new cotter pin is put in and the transaxle then refilled using the approved lubricant.

Related Kia Optima Parts

Browse by Year

2020 Axle Shaft 2019 Axle Shaft 2018 Axle Shaft 2017 Axle Shaft 2016 Axle Shaft 2015 Axle Shaft 2014 Axle Shaft 2013 Axle Shaft 2012 Axle Shaft 2011 Axle Shaft 2010 Axle Shaft 2009 Axle Shaft 2008 Axle Shaft 2007 Axle Shaft 2006 Axle Shaft 2005 Axle Shaft 2004 Axle Shaft 2003 Axle Shaft 2002 Axle Shaft 2001 Axle Shaft 2000 Axle Shaft