×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sorento Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Brake Discs found

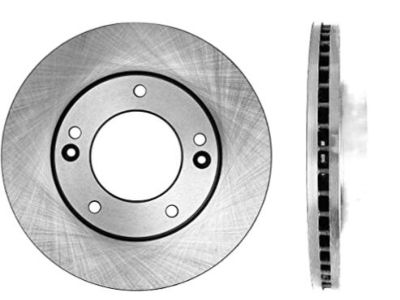

Kia Sorento Disc-Front Wheel Brake

Part Number: 51712C6000$104.65 MSRP: $151.02You Save: $46.37 (31%)Ships in 1-2 Business Days

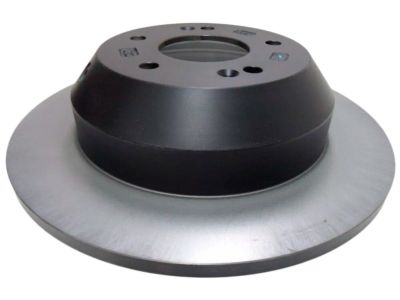

Kia Sorento Disc Assembly-Rear Brake

Part Number: 584112P000$102.95 MSRP: $148.55You Save: $45.60 (31%)Ships in 1-3 Business Days

Kia Sorento Disc-Front Wheel Brake

Part Number: 517124Z000$98.50 MSRP: $142.14You Save: $43.64 (31%)Ships in 1-3 Business Days

Kia Sorento Disc Assembly-Rear Brake

Part Number: 58411C6000$115.87 MSRP: $168.67You Save: $52.80 (32%)Ships in 1-3 Business Days

Kia Sorento Disc-Front Wheel Brake

Part Number: 517121U000$97.29 MSRP: $140.39You Save: $43.10 (31%)Ships in 1-2 Business Days

Kia Sorento Disc-Front Wheel Brake

Part Number: 517123E700$87.54 MSRP: $126.32You Save: $38.78 (31%)Ships in 1-3 Business Days

Kia Sorento Disc Assembly-Rear Brake

Part Number: 58411C5000$106.69 MSRP: $145.75You Save: $39.06 (27%)Ships in 1-3 Business Days

Kia Sorento Disc-Brake,Front

Part Number: 517123E400$87.54 MSRP: $126.32You Save: $38.78 (31%)Ships in 1-3 Business Days

Kia Sorento Disc-Brake

Part Number: 456524C000$37.17 MSRP: $50.79You Save: $13.62 (27%)Ships in 1-3 Business DaysKia Sorento Disc-Rear Brake

Part Number: 584113E500$67.34 MSRP: $97.17You Save: $29.83 (31%)Ships in 1-3 Business DaysKia Sorento Disc-Brake,Front

Part Number: 517123E200$92.46 MSRP: $126.32You Save: $33.86 (27%)Ships in 1-3 Business DaysKia Sorento Disc-Front Wheel Bra

Part Number: 51712R5000$132.76 MSRP: $193.25You Save: $60.49 (32%)Ships in 1-3 Business DaysKia Sorento Disc-Front Wheel Bra

Part Number: 51712P2000$111.11 MSRP: $160.34You Save: $49.23 (31%)Ships in 1-3 Business DaysKia Sorento Disc Assembly-Rr Brake

Part Number: 58411P2700$101.00 MSRP: $145.75You Save: $44.75 (31%)Ships in 1-3 Business DaysKia Sorento Disc Assembly-Rr Brake

Part Number: 58411R5000$110.37 MSRP: $159.27You Save: $48.90 (31%)Ships in 1-3 Business Days

Kia Sorento Brake Disc

If you're in search of top-notch, reasonably priced OEM Kia Sorento Brake Disc, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sorento Brake Disc, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sorento Brake Disc Parts Questions & Experts Answers

- Q: How to replace a brake disc on Kia Sorento?A:Loosen the wheel lug nuts, raise the vehicle, and support it securely on jackstands. Remove the wheel and install the lug nuts to hold the disc in place, releasing the parking brake if working on the rear brake disc. Remove the Brake Caliper without disconnecting the brake hose, suspending it out of the way with a piece of wire. Remove the caliper bracket bolts and take off the bracket. Visually inspect the disc surface for score marks and other damage; light scratches and shallow grooves are normal, but deep scoring over 0.039-inch requires disc removal and refinishing. Check both sides of the disc, and if pulsating occurs during brake application, suspect disc runout. To check runout, place a dial indicator about 1/2-inch from the outer edge of the disc, set it to zero, and turn the disc, ensuring the reading does not exceed the allowable runout limit. Professionals recommend resurfacing the discs whenever the pads are replaced to ensure a smooth finish and eliminate brake pedal pulsation. If not resurfacing, remove the glaze from the surface with sandpaper or emery cloth using a swirling motion. Ensure the disc is not machined to a thickness under the specified minimum allowable refinish thickness, which can be checked with a micrometer. Remove the lug nuts that were used to hold the disc in place, take out the Phillips-head screws from the disc, and slide the disc off the hub. Place the new disc in position over the threaded studs, install the caliper, and tighten the bolts to the specified torque, bleeding only if the brake hose was disconnected. For rear discs, check the adjustment of the parking brake. Finally, install the wheel and lug nuts, lower the vehicle, tighten the lug nuts to the specified torque, and check the operation of the brakes carefully before driving.

Related Kia Sorento Parts

Browse by Year

2023 Brake Disc 2022 Brake Disc 2021 Brake Disc 2020 Brake Disc 2019 Brake Disc 2018 Brake Disc 2017 Brake Disc 2016 Brake Disc 2015 Brake Disc 2014 Brake Disc 2013 Brake Disc 2012 Brake Disc 2011 Brake Disc 2010 Brake Disc 2009 Brake Disc 2008 Brake Disc 2007 Brake Disc 2006 Brake Disc 2005 Brake Disc 2004 Brake Disc 2003 Brake Disc