×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Kia Parts

- Kia Accessories

My Garage

My Account

Cart

Genuine Kia Sorento Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Universal Joints found

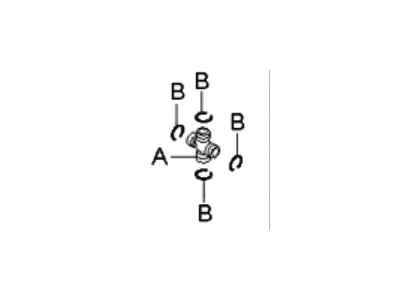

Kia Sorento Joint Kit-Universal

Part Number: 495983E200$95.65 MSRP: $130.67You Save: $35.02 (27%)Ships in 1-3 Business DaysKia Sorento Joint Assembly-Universal

Part Number: 0W00125060A$88.29 MSRP: $127.40You Save: $39.11 (31%)Ships in 1-3 Business DaysKia Sorento Joint Kit-Universal

Part Number: 495983E000$95.65 MSRP: $130.67You Save: $35.02 (27%)Ships in 1-3 Business Days

Kia Sorento Universal Joint

If you're in search of top-notch, reasonably priced OEM Kia Sorento Universal Joint, then you've found the perfect spot. Our website boasts an extensive inventory of Kia Sorento Universal Joint, all priced at the market's premier price. Rest assured, every genuine part we offer comes with a warranty straight from the manufacturer.

Kia Sorento Universal Joint Parts Questions & Experts Answers

- Q: How to replace a universal joint in a driveshaft on Kia Sorento?A:This procedure seems to require a large vise or a press and it might be wiser to take the driveshaft to a dealer service department or a service station or a machine shop as a place where to replace a universal joint. It is advised to start with the driveshaft being taken out first. Remove the snap-rings of the spider using pliers to remove them. When supporting the driveshaft place it on a workbench that has a vise , preferably on a section of the driveshaft that is not being worked on at that point of time. Lie one bearing cap flat on a bench and position a piece of pipe or a large socket over it whose inside diameter is only slightly larger than the outside diameter of the bearing caps; place a socket with an outside diameter slightly smaller than the opposite bearing cap over that cap and then use the vise or press to force the bearing cap out. Apply the vise or large pliers to push out bearing cap the rest of the way out. Move the said sockets to opposite sides and applying the same amount of pressure, push the other bearing cap out. Grease the new joints with high-grade grease and if there are any extra special instructions on the package on the universal joint then they must be followed several times. Insert the spider into the yoke, and partially slot in one bearing cap before beginning to start the spider into the bearing cap and then only partially slotting in the other bearing cap. Tighten the bearing caps securely while maintaining the spider in the right position while at the same time avoiding a situation that can destroy dust seals. Finally apply use the smaller socket to apply pressure the caps on until they sit fully in their recessed positions and finally fit the snap-rings on. If there is pain in seating them, use a hammer and strike the driveshaft yoke on the required area to make the yoke ears to expand a little to enable the snap-rings to be seated on their slots. If it is not possible to make the snap-ring sit correctly, striking the yoke with a brass hammer holds the possiblity of releasing tension and slightly springing the yoke ears. Before reinserting the driveshaft, screw in the grease fitting now if your universal joint is equipped with one and fill the joint with grease using a grease gun to add more.